Flat bottom silos type BIN20 with sidewalls made of flat sheets of steel. Diameter of 2,29 metres. Loading capacity from 19,7 tonnes to 33,8 tonnes

Technical data of the silos type BIN20:

|

model |

NBIN20N |

NBIN20 |

NBIN20R |

NBIN20W |

NBIN20WR |

NBIN20WW |

|

capacity (volume) |

26,3m3 |

29,9m3 |

29,9m3 |

37,4m3 |

37,4m3 |

45m3 |

|

loading capacity for wheat with density of 750 kg/m3 |

19,7t |

22,4t |

22,4t |

28,1t |

28,1t |

33,8t |

|

height from the anchoring level to the loading inlet in the top of silo |

4,3m |

4,8m |

4,8m |

5,75m |

5,75m |

6,7m |

|

diameter |

3,19m |

3,19m |

3,19m |

3,19m |

3,19m |

3,19m |

|

net weight of the silo components |

820kg |

861kg |

894kg |

984kg |

1016kg |

1161kg |

|

weight and number of the floor supports made of concrete (weight and number of concrete blocks that support silo floor) |

75 pieces (698kg) |

75 pieces (698kg) |

75 pieces (698kg) |

75 pieces (698kg) |

75 pieces (698kg) |

75 pieces (698kg) |

Standard equipment:

- essential components:

- shell made of flat sheets of steel

- anchors for fixing to the foundation

- roof designed for snow load on the ground of 1,6 kN/m2

- set of fasteners made of steel with anti-corrosive coating

- means of access:

- roof hatch with protective covers

- external ladder with safety cage and protection against unauthorized entry

- internal ladder with safety cage

- ventilation:

- perforated floor made of steel with perforation on entire surface

- air inlet with diameter of 180mm for connecting a fan

- water pressure manometer

- loading and unloading:

- central loading inlet with a diameter of 200mm located in the top of roof

- side loading inlet

- loading pipe intended to the side inlet, 2m long for the NBIN20N silo, NBIN20 silo, NBIN20R silo and 3m long for the NBIN20W silo, NBIN20WR silo and 4m long for the NBIN20WW silo

- bag filling device

- anti-dynamic pipe of the bag filling device in NBIN20WW silo

- discharge sleeve in the silo NBIN20R and silo NBIN20WR

Optional equipment:

- means of access:

- bottom access manhole with double door and anti-slip platform

- ventilation:

- fan forcing air (recommended PPZ fan)

- extraction fan model OWS250-10-200 designed to mount it on the roof

- temperature probe with 4-points of measuring NBIN20N, NBIN20, NBIN20R, NBIN20W and NBIN20WR silos; temperature probe with 6-points of measuring for the NBIN20WW silo

- 4,5kW air heater

- loading and unloading:

- discharge sleeve dedicated for the silos without sleeve in standard specification

- extension of the discharge sleeve

- hopper inlet mounted to the central loading inlet designed for loading the silo with an inclined screw auger conveyor

- control module of the silo model MKS-100

- underfloor screw auger conveyor model PS160 for silo unloading

- blower designed for conveying the grain

- vertical screw auger conveyor

Recommended means of loading and unloading for silos type BIN20:

|

loading |

unloading |

|

blower designed for conveying the grain |

bag filling device |

|

inclined screw conveyor |

universal screw conveyor through the discharge sleeve |

|

vertical screw conveyor type PS220-PN |

underfloor screw auger conveyor model PS160 |

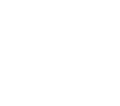

Technical drawing of the NBIN20N silo:

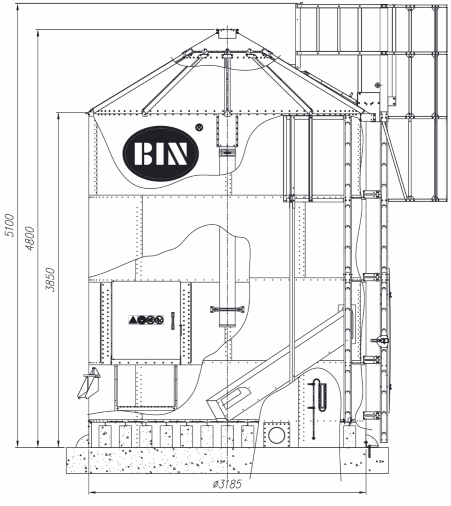

Technical drawing of the NBIN20R silo:

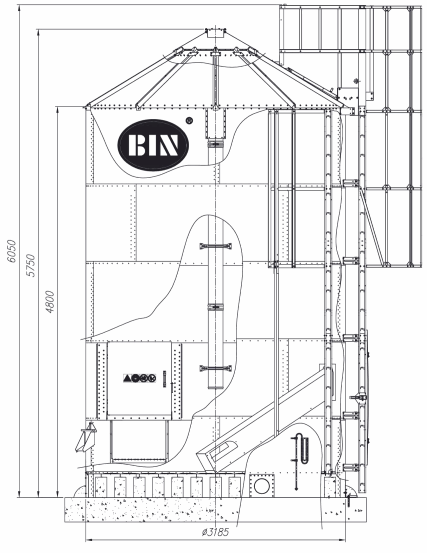

Technical drawing of the NBIN20WR silo:

Technical drawing of the NBIN20WW silo:

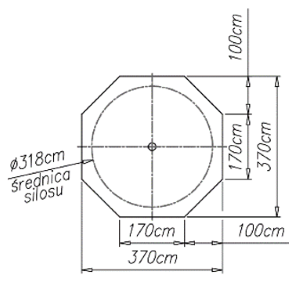

Guidelines for producing a foundation slab for silo type BIN20:

|

silo type |

BIN20 |

|

minimum thickness of the foundation slab |

30cm |

|

minimum class of concrete |

C20/25 (B25) |

|

reinforcement |

ribbed steel class A-IIIN (B500SP) double cross-reinforced mesh ?12 every 25cm top covering and bottom covering 5cm thick meshes rotated by 45° |

|

number of drains (o) |

1 piece |

|

|

|

|

|

|

|