Flat bottom silos type BIN1500 with sidewalls made of flat sheets of steel. Diameter of 14,33 metres. Loading capacity from 1170 tonnes to 1744 tonnes

Technical data of the silos type BIN1500:

|

model |

NBIN1500_N |

NBIN1500_P |

NBIN1500 |

NBIN1500W |

|

capacity (volume) |

1560m3 |

1713m3 |

2019m3 |

2325m3 |

|

loading capacity for wheat with density of 750 kg/m3 |

1170t |

1285t |

1514t |

1744t |

|

height from the anchoring level to the loading inlet in the top of silo |

12,7m |

13,65m |

15,5m |

17,4m |

|

diameter |

14,33m |

14,33m |

14,33m |

14,33m |

|

net weight of the silo components |

17682kg |

18504kg |

20452kg |

22988kg |

|

weight and number of the floor supports made of concrete (weight and number of concrete blocks that support silo floor) |

1800 pieces (16740kg) |

1800 pieces (16740kg) |

2200 pieces (20460kg) |

2200 pieces (20460kg) |

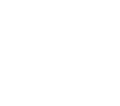

Standard equipment:

- essential components:

- shell made of flat sheets of steel

- anchors for fixing to the foundation

- roof designed for snow load on the ground of 1,6 kN/m2

- set of fasteners made of steel with anti-corrosive coating

- means of access:

- roof hatch with access platform and protective covers

- internal ladder with safety cage

- bottom access manhole with double door and anti-slip platform

- ventilation:

- perforated floor made of steel with perforation on entire surface

- air inlet with diameter of 400mm for connecting a fan

- water pressure manometer

- roof exhausters – 32 pieces

- loading and unloading:

- central loading inlet with a diameter of 300mm located in the top of roof

- emergency outlet of grain

Optional equipment:

- means of access:

- external ladder with safety cage and protection against unauthorized entry and resting platform

- spiral stairs

- roof stairs

- platform to the roof collar

- service catwalk

- ventilation:

- fan forcing air

- universal air inlet with valve that helps to connect one fan into two silos

- extraction fan model OWS250-500+ designed to mount it on the roof

- temperature probe with 10-points of measuring for the NBIN1500_N silo, temperature probe with 12-points of measuring for the NBIN1500_P silo, temperature probe with 14-points of measuring for the NBIN1500 and NBIN1500W silos

- loading and unloading:

- bucket elevator

- control module of the silo MKS-100

- underfloor conveyor designed for silo unloading (recommended PS220 screw auger conveyor or RED250 chain conveyor)

- internal sweep auger conveyor PSW1500

Recommended means of loading and unloading for silos type BIN1500:

|

loading |

unloading |

|

bucket elevator type PK250 |

underfloor screw auger conveyor model PS220 with internal sweep auger conveyor PSW-1500 |

|

underfloor chain conveyor model RED250 with internal sweep auger conveyor PSW-1500 |

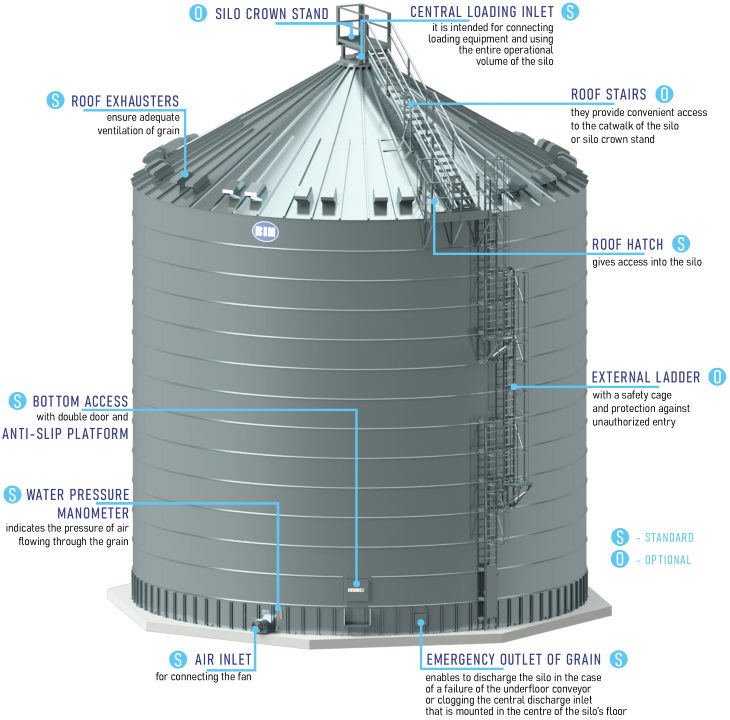

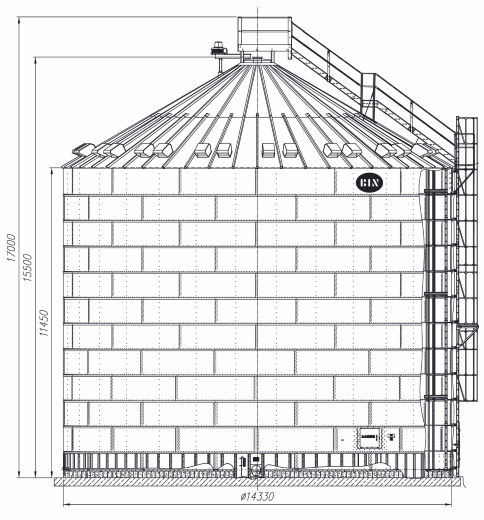

Technical drawing of the NBIN1500_N silo:

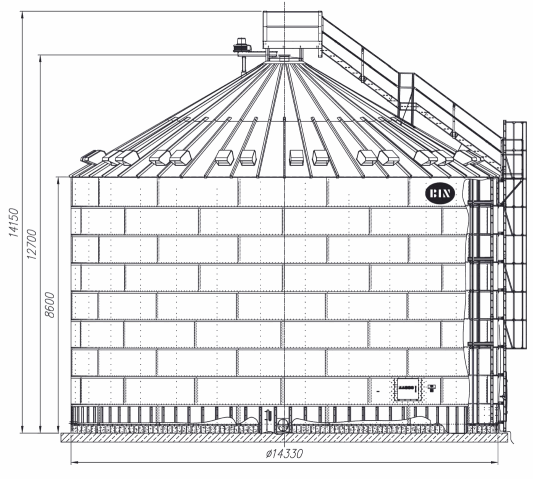

Technical drawing of the NBIN1500_P silo:

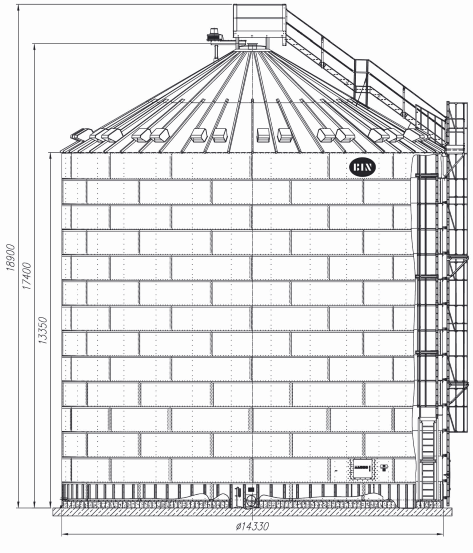

Technical drawing of the NBIN1500 silo:

Technical drawing of the NBIN1500W silo:

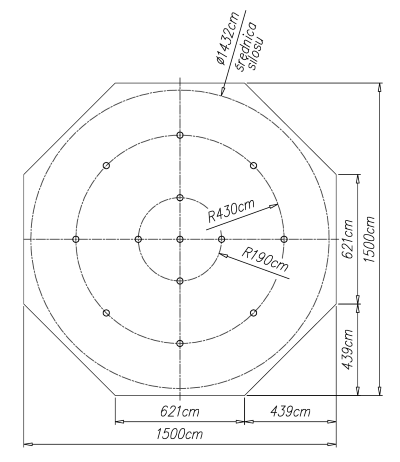

Guidelines for producing a foundation slab for silo type BIN1500:

|

silo type |

BIN1500 |

|

minimum thickness of the foundation slab |

30cm |

|

minimum class of concrete |

C20/25 (B25) |

|

Reinforcement of an octagonal plate |

ribbed steel class A-II double cross-reinforced mesh f12 every 24cm, and double cross-reinforced mesh f12 concentrated on the side edges (side margins) of the foundation slab top covering and bottom covering 5cm thick meshes rotated by 45° |

|

Reinforcement of a round plate |

ribbed steel class A-II double cross-reinforced mesh bottom reinforcement Φ12 every 25cm top reinforcement Φ16 every 17cm top covering and bottom covering 5cm thick meshes rotated by 45° |

|

number of drains (o) |

13 pieces |

|

|

|