Flat bottom silos type FBIN14 with sidewalls made of corrugated sheets of steel. Diameter of 14,3 metres. Loading capacity from 1606 tonnes to 2609 tonnes

Technical data of FBIN14 silo type:

|

model |

FBIN14/10 |

FBIN14/11 |

FBIN14/12 |

FBIN14/13 |

FBIN14/14 |

FBIN14/15 |

FBIN14/16 |

FBIN14/17 |

|

nominal capacity (volume) |

2059m3 |

2243m3 |

2427m3 |

2610m3 |

2794m3 |

2978m3 |

3161m3 |

3345m3 |

|

loading capacity for wheat with density of 780kg/m3 |

1606t |

1749t |

1893t |

2036t |

2179t |

2323t |

2466t |

2609t |

|

height from the anchoring level to the loading inlet in the top of silo |

15,57m |

16,71m |

17,85m |

18,99m |

20,13m |

21,27m |

22,41m |

23,55m |

|

diameter |

14,3m |

14,3m |

14,3m |

14,3m |

14,3m |

14,3m |

14,3m |

14,3m |

The loading capacity is calculated for nominal volume of the silo.

Actual capacity of the silo may vary, because it depends on many factors, such as: technology of preparing ventilation ducts, method of loading, type of equipment used inside the silo, grain bulk properties, etc.

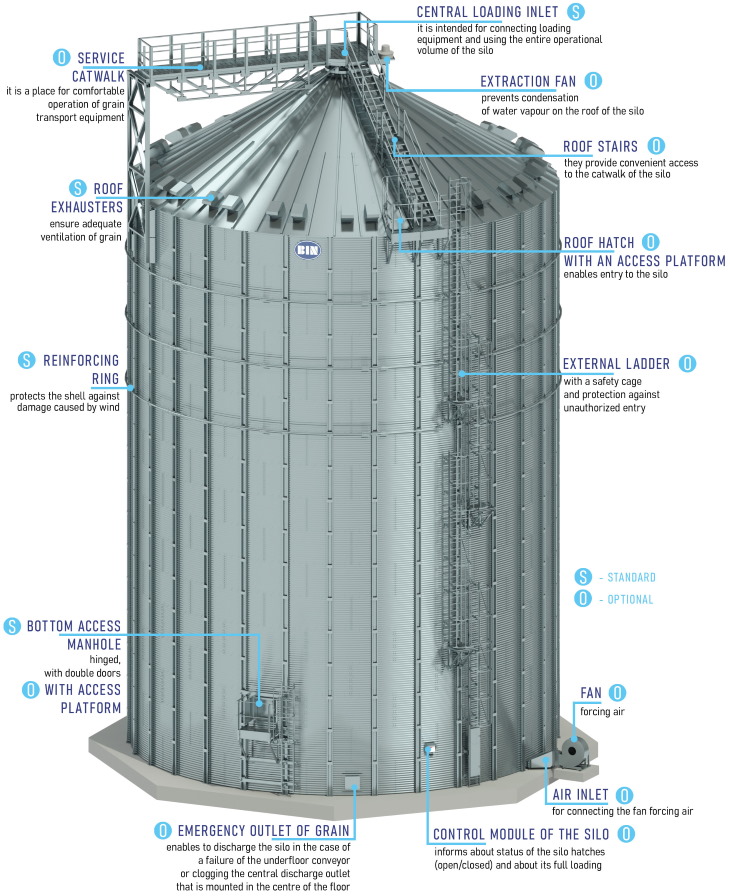

Standard equipment:

- shell made of corrugated sheets of steel

- anchors for fixing to the foundation

- roof designed for a snow zone of 200kg/m2

- 32 exhausters on the roof

- central loading inlet with a diameter of 300mm located on the top of the roof

- hinged bottom access manhole with double doors

- internal ladder to the bottom access manhole

- service hole located on the roof with a safety grille

- rings protecting the shell of silo against wind actions and strengthening the shell

Optional equipment:

- means of access:

- external ladder with safety cage and protection against unauthorized entry

- internal ladder with protection

- additional bottom access manhole

- roof stairs

- roof hatch with an access platform

- catwalk to cover whole diameter of the silo or half diameter of the silo

- platform on the top rim of the silo to use when the catwalk is not needed

- access platform with ladder or lower platform enable access to the bottom access manhole

- ventilation:

- fully perforated floor made of steel based on a concrete blocks or on a truss made of steel

- ventilation ducts in the concrete floor

- air inlets for connecting the fan forcing air

- fan forcing air

- extraction fan on the silo roof

- temperature measurement probe

- loading and unloading:

- control module of the silo

- emergency outlet of grain (portable duct designed for grain unloading located on the silo floor)

- internal sweep auger conveyor

- underfloor conveyor for silo unloading